Industrial dryer are most typically used setup in several kind of industrial process applications, key exertion of industrial dryers are to eliminate or remove moisture, water and different solvents from the material under processing. Industrial dryers should be carefully designed so that not to change or affect the physical, chemical or biological property of material, since industrial dryers are in-built various kinds of shapes with different specification, choice of right dryer is the key for processing.

At Kerone, we are having more than 46 years’ experience in helping various types of industries with designing, manufacturing and installation of various types of custom build industrial drying solution. We help the client in selection by understanding the prerequisite for quality, size, shape and moisture content of the ultimate dried product have to be taken into contemplation, as well as production setting, construction materials most common stainless steel, energy consumption pattern. The feeding type and amount of material to be fed.

Industrial dryers made by Kerone are efficient, effective and controllable with fast and controlled reaction time for removing of water/moisture .At Kerone we are having immense range of industrial dryers that may suit to numerous vital application across industries such are chemical, pharmaceutical, food, aviation, Oil & Gases, wood, paper production, ceramics and many more. Our specialities are in designing, manufacturing and installation of numerous kinds of specialised and generalised Industrial dryers those is simply amended in various industrial application:

We provide Industrial drying solution best on the requirement of client processing for different shapes and sizes

1) Lab scale:

Lab scale industrial dryers are suitable for the small quantity production or laboratory experiments. At Kerone, to cater with need of these pilot plants/ lab scale industrial dryers we provide the solution that can be of both batch type or conveyer based systems.

Typical application of lab scale equipment are:

- Experiments at Laboratories

- Production of small quantity

- Processing of Chemical

- Preheating

- High temperature processing

2) Batch scale/Type Industrial Dryers:

Drying is amongst the very important process in almost all industrial processes, some manufacturing firms requires to process the material in batches or some high temperature drying materials are done in batches. Batch type industrial dryers are intended to have suitable doors for loading and unloading the trays with the material to be dried. It’s build with an extensive mixed container of shapes and sizes as per the application. It’s consolidated with both, basic operation and high solidness. Chambers are designed to achieve uniform warming all through. Typical application of batch type equipment are:

- Tray drying

- Drum drying

- Rotary drying

3) Continuous Type Industrial Dryers:

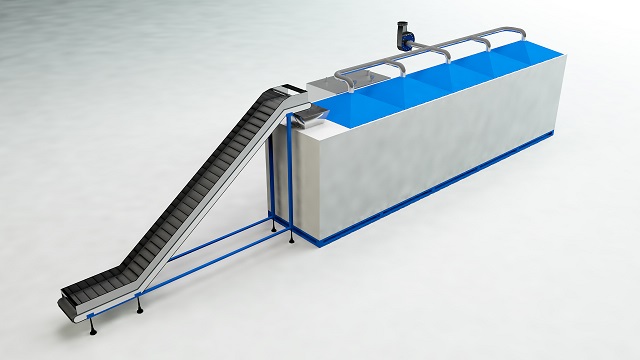

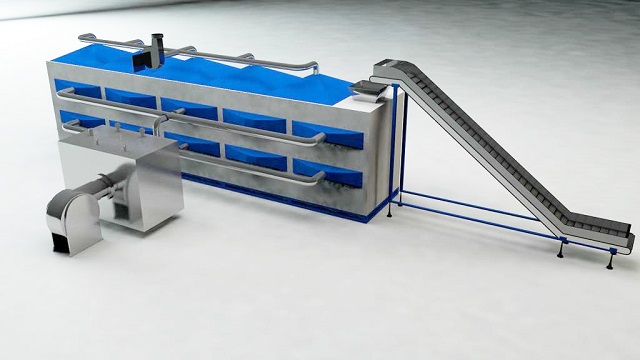

Continuous type industrial dryers are labour free dryers, it does not require manual feeding door opening, whereas continuous type industrial dryers are integrated with existing production line conveyer. The key for the success of dried material is conveyer speed, which decides the time for which the material will be under specified temperature zone. For most of application continuous industrial dryers, demonstrate an enhanced performance as compared to other type of dryers.

Typical application of batch type equipment are:

- Pharmaceutical application

- Textile drying

- Paper drying

- Packaging industries

- Ceramic Industries

In last 48 years, we have designed and fulfilled the requirements of many type of industries with various type of industrial dryers, below are the few Industrial dryers listed however, the experience is endless:

|

|

Industrial Dryer Selection

Typical selection parameters are as below:

|

|

Application :

Practically the applications of industrial dryers and drying equipment are endless they are required approximately in all the industrial processing:

|

|

Features:

Kerone design and build the industrial dryers to continuously reproduce the best result for the material under processing, below are the few key feature of our solutions:

- Highly controllable design and technology

- Accurately calculated processing time

- Minimum handling

- Low cost of operation

- Controlled noise level

- Compact construction

- Minimum Maintenance

- Accurately calibrated

- Uniform drying temperature is assured

- Energy saving

- Less fuel consumption