Corrugation Heater

At KEROENE we have strived very hard to provide best quality Corrugation heater, as of now we have designed and manufactured various types of corrugation heater named on the process need of client.

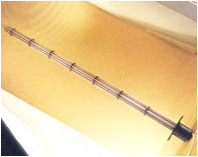

Corrugations heaters are most commonly find its application to heat the rolls and turn form flute on the paper in corrugation machine, hence most commonly known as corrugation machine heater. Corrugation heaters designed at KERONE is strictly as per the norms and as per the required specifications of corrugation machines. The heating material used is of vey high quality and can very easily maintained and replaced if needed. It saves power consumption by its quick heating ability which is the USP of the KERONE’s products.

The use of indents In the world of production, heaters are essential, especially in sectors where the conversion of raw materials into final products is crucial. Its main purpose is to precisely apply heat to materials that are corrugated, like cardboard, paper, or polymers, so that they can be precisely manipulated and shaped. This technology opens up a world of creative possibilities for manufacturers all over the world by utilizing controlled heat to create complicated patterns and structures with ease.The Corrugation Heater’s design is based on the principles of durability, adaptability, and efficiency. Each item is made using premium materials and rigorously tested to ensure lifespan and performance even in the most challenging circumstances. This symbolizes a commitment to excellence. Because of its modular design, it is simple to integrate into current production lines, reducing downtime and optimizing processes for peak output.The Corrugation Heater’s sophisticated heating technique, which combines convective and radiant heat transfer methods to produce the best results, is one of its primary differentiators. Through accurate regulation of temperature gradients and airflow patterns, this novel method guarantees consistent heating throughout the material’s surface area, thereby eradicating hot spots and thermal irregularities. The outcome is a faultless final product with perfect structural integrity and visual attractiveness.The Corrugation Heater’s versatility is its main selling point because it may be used for a wide range of industrial applications. Whether producing packing goods, signage, or architectural components, this versatile tool excels at producing results that are consistently good on a range of surfaces and thicknesses. Because of its easily adjustable settings, operators can easily get ideal results by fine-tuning parameters to meet unique needs.Additionally, Corrugation Heater promotes environmental responsibility and sustainability. It is consistent with eco-conscious production principles by maximizing energy efficiency and decreasing waste, assisting companies in lessening their carbon footprint and making a positive impact on the environment. Its lengthy service life and sturdy design also contribute to its overall low resource consumption, which enhances its eco-friendliness.Features of Corrugation Heater

- Longer functional life

- Low and easy maintenance

- Dense construction

- Quick and Easy installation

- Precisely designed and engineered

- Hassle-free functioning

- Longer service life

- Rugged construction

- High durability

- Energy and Cost efficient

- Power saving

- Efficient performance

Specification:

- In the KERONE MODEL, the outer diameter is 8 mm O.D

- In the STANDARD MODEL, the outer diameter is 10.8 mm O.D, giving it a longer durability. For faster heating purposes, High Speed Models are available at 9 KW (+).

Quality is not an accident, it is a constant process to improve. Availability:

| Machine Sizes | KW | Models |

|---|---|---|

| 32″ M/C | UPTO 7 KW | Kerone/Standard |

| 42″ M/C | UPTO 9KW | Kerone/Standard |

| 45″ M/C | UPTO 9 KW | Kerone/Standard/High Speed |

| 52″ M/C | UPTO 12 KW | Kerone/Standard/High Speed |

| 62″ M/C | UPTO 15 KW | Kerone/Standard/High Speed |

| 65″ M/C | UPTO 15 KW | Kerone/Standard/High Speed |

| 72″ M/C | UPTO 18KW | Kerone/Standard/High Speed |

| 82″ M/C | UPTO 18KW | Kerone/Standard/High Speed |

Product Catalogue

2023-2024

Click to download our latest catalogue and see the products and configuration

Browse by Category

- Industrial Dryer

- Industrial Ovens

- Rotary Dryers

- Cold Plasma for Sterilization

- Microwave Heating systems

- Agitated Thin Film Dryer (ATFD)

- Dehydrator

- Biochar Processing Line

- Coating Lines

- Processing / Production Line

- Heating and Cooling Systems

- Process Equipment

- Drum Heating Ovens

- Ethanol Recovery Plant

- Sludge Drying Systems Or Sludge Dryers

- Sulphur Melting And Granule Plant

- Wet Laid Paper Plant / Machines

- Pulp Packaging Dryer

- Potato Powder Production Plant

- Hot Air Dryer

- Lube Oil Blending Drum Ovens

- Infrared Piston Rod Heating Systems

- PTFE Powder Drying Line

- Hot Melt Adhesive Mixing Plant

- Infrared Heating Equipments

- Basics Of Radio Frequency Heating

- Soap Stock Drying Systems

- Infrared Paper Coating Dryers

- Plastic Annealing Ovens

- Electric Oven For HT/LT Motors

- Fuel Fired Heating System

- Umbrella Infrared Dryers

- Industrial Heating Equipments

- Industrial Heaters

- Infrared Heating System

- Gas Infrared Burner (MFB IR Burner)

- Lab Equipments

- Infrared Heaters

- Infrared Surface Heating System

- PLC & Automation Panel

- INDUSTRIAL DRYERS

- Rotary Dryers

- Tower Dryers

- Tray Dryers

- Fish Dryer

- Spiral Conveyor Dryers

- Microwave Spices Dryer

- Food Dryers

- Grain Dryers

- Freeze Dryers

- Coir Pith Dryers

- Conveyorised Organic Waste Dryers

- ROTARY DRYER

- Biomass Dryer

- Coal Palm Slag Rotary Dryer

- Coal Rotary Dryer

- Coal Slime Rotary Dryers

- Coal Steam Type Rotary Dryer

- Coconut Coir Dryer

- Cow Dung Rotary Dryer

- Elephant Grass Dryer

- Mineral Slag Rotary Drum Dryer

- Organic Fertilizer Plant

- Paddle Rotary Dryer

- Paddle Stirring Drum Rotary Dryer

- Poultry Manure Rotary Dryer

- Rotary Drum Sawdust Dryer

- Sand Rotary Dryer

- Three Channel Drum Rotary Dryer