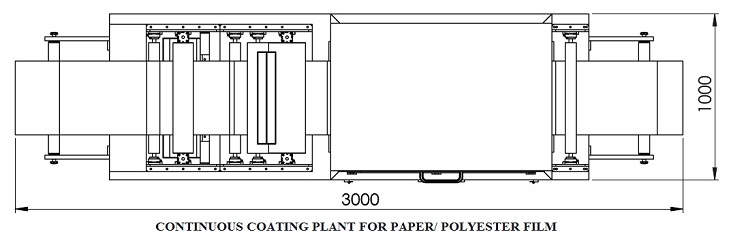

Cast Coating Line

Coating or Casting machines are commonly used to produce a thin and thick layer of solvents or aqueous-based slurries. Machines designed and developed by Kerone meet the latest state of art specifications that produce desired results in successfully casting and coating of ceramics, metals and composite tape cast. Kerone has proved its metal in coating/casting industries with its quality and cost-effective engineering solutions.

Cast Coating Line machines are commonly used to produce a thin and thick layer of solvents or aqueous-based slurries. The machines made and manufactured by Kerone conform to advanced standards for successful metallography, metal casting and metal coating of ceramics, metals, and composite tape casts. Kerone’s engineering solutions have been effective as they have delivered on quality at a reasonable cost especially to industries concerned with coating or casting.

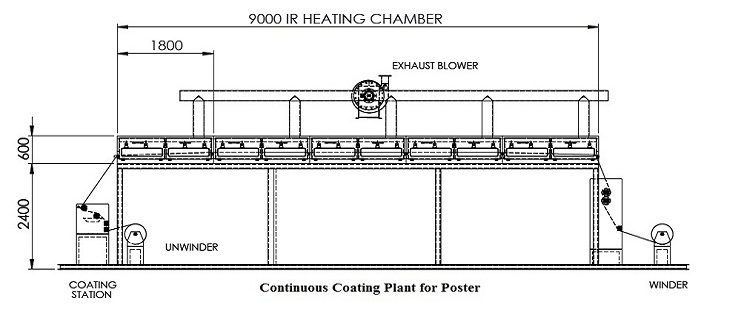

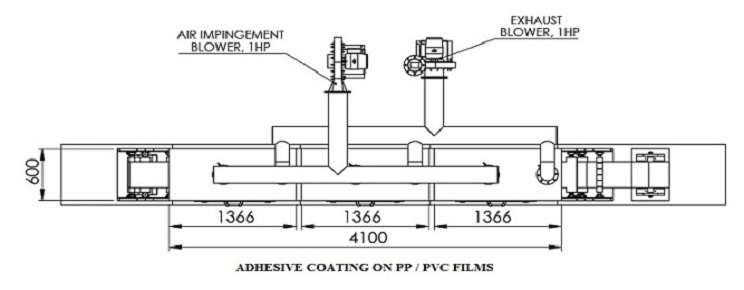

The cast coating line assembly is made using a rigid and stable steel design that creates completely uniform movements of the web on its surface. This coater/cast should also be designed depending upon the need for coating or casting it. Kerone machines have modern microprocessor closed loop, feed-back electronic controls used to determine the film uniformity. The standard tape Cast Coating Line manufactured by Kerone is a popular machine for laying down the desirable layer at optimum accuracy.Applicators are equally matched by the drying chamber which is also a crucial part of coating or casting systems. The drying space requires continuous air drawn on the film and simultaneously blown over the moving web from the opposite direction. If the bed heaters are equipped with temperature controllers and run until maximum drying of machines is achieved would produce even a more effective result than lengthening process of machines.Features of Cast Coating Line

- Coating thickness

- Coating Material

- The thickness of coating film

- Maintaining smoothness of coating material’s viscosity

- Drying techniques

- Control and feedback mechanism

- Coating/casting Speed

- Surface study

- Airflow

- Solvent gradient

Kerone’s objective has been clear to provide the best quality advanced and custom-designed machines that can provide high efficiency, repeatable performance with the best result every time, reduced maintenance, and easy to operate.

KERONE is pioneer in application and implementation engineering with its vast experience and team of professionals. KERONE is devoted to serve the industry to optimize their operations both economically and environmentally with its specialized heating and drying solutions.

Product Catalogue

2023-2024

Click to download our latest catalogue and see the products and configuration

Browse by Category

- Industrial Dryer

- Industrial Ovens

- Biochar Processing Line

- Cold Plasma for Sterilization

- Microwave Heating systems

- Dehydrator

- Mixing Kettle

- Coating Lines

- Process Equipment

- Processing / Production Line

- Heating and Cooling Systems

- Drum Heating Ovens

- Infrared Piston Rod Heating Systems

- Sulphur Melting And Granule Plant

- Wet Laid Paper Plant / Machines

- Ethanol Recovery Plant

- Sludge Drying Systems Or Sludge Dryers

- Pulp Packaging Dryer

- Potato Powder Production Plant

- Hot Air Generator

- Lube Oil Blending Drum Ovens

- PTFE Powder Drying Line

- Hot Melt Adhesive Mixing Plant

- Industrial Heaters

- Infrared Heating Equipments

- Basics Of Radio Frequency Heating

- Soap Stock Drying Systems

- Infrared Paper Coating Dryers

- Fuel Fired Heating System

- Electric Oven For HT/LT Motors

- Plastic Annealing Ovens

- Umbrella Ir Dryer For Pharma

- Industrial Heating Equipments

- Infrared Heating System

- Gas Infrared Burner ( MFB IR Burner ) -

- Lab Equipments

- Infrared Heaters

- PLC & Automation Panel

- Infrared Surface Heating System

- Rotary Dryers

- INDUSTRIAL DRYERS

- Rotary Dryers

- Tower Dryers

- Tray Dryers

- Fish Dryer

- Spiral Conveyor Dryers

- Microwave Spices Dryer

- Food Dryers

- Grain Dryers

- Freeze Dryers

- Coir Pith Dryers

- Conveyorised Organic Waste Dryers

- ROTARY DRYER

- Biomass Dryer

- Coal Palm Slag Rotary Dryer

- Coal Rotary Dryer

- Coal Slime Rotary Dryers

- Coal Steam Type Rotary Dryer

- Coconut Coir Dryer

- Cow Dung Rotary Dryer

- Elephant Grass Dryer

- Mineral Slag Rotary Drum Dryer

- Organic Fertilizer Plant

- Paddle Rotary Dryer

- Paddle Stirring Drum Rotary Dryer

- Poultry Manure Rotary Dryer

- Rotary Drum Sawdust Dryer

- Sand Rotary Dryer

- Three Channel Drum Rotary Dryer